spawarka łuk aluminium podwójny impuls ALUMIG-300P

- model

- ALUMIG-300P

nieruchomość

- Znamionowe napięcie wejściowe

- 3PH ~ 400V ± 15%

- MAX.Load Power Capacity

- 12.04KVA

- Znamionowe wyjście

- 250A / 26,5V

- Maksymalne napięcie obwodu otwartego

- 70V ~ 80V

- Efektywność

- 80%

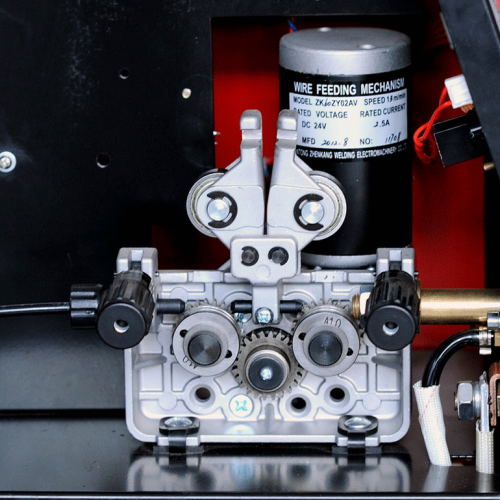

- Mechanizm podawania drutu

- 4 Walce

- Zakres prędkości podawania drutu

- 0 ~ 25 m / min

- Gwarancja

- 1 rok gwarancji

- Wymiar

- 790X250X650mm

- Waga

- 32 kg

Ocena

Opis produktu

-

ALUMIG-300P

Strong power, Multi-functions,Superb performance and Economical choice.

-

Application:

Metal Fabrication

Maintenance and Repair

Auto Body

Light Industrial -

Processes:

MIG

Flux-Cored

Pulse MIG

Double Pulse MIG

MMA(Stick) -

Input Power: 400V, 1-Phase

Range: 10-250A

Rated Output at 40°C (104°F):

250A at 26.5V @60% Duty Cycle

Weight: 32KG

SYNERGY MIG

The synergic operation of the machine makes it easy to use, even for the beginning welder. Simply set wire type and diameter, then choose a wire speed. Now you’re off to weld! As wire speed increases/decreases, the arc voltage also increases/decreases to maintain a constant welding arc.

PULSE MIG

The Pulsed MIG process works by forming one droplet of molten metal at the end of the electrode per pulse. Then, just the right amount of current is added to push that one droplet across the arc and into the puddle. The transfer of these droplets occurs through the arc, one droplet per pulse.

Advantage:

- Absent or very low levels of spatter.

- More resistant to lack of fusion defects than other modes of GMAW metal transfer.

- Excellent weld bead appearance.

- Reduced levels of heat induced distortion.

- Ability to weld out-of-position.

- Lower hydrogen deposit.

- Reduces the tendency for arc blow.

- Lends itself to robotic and hard automation applications.

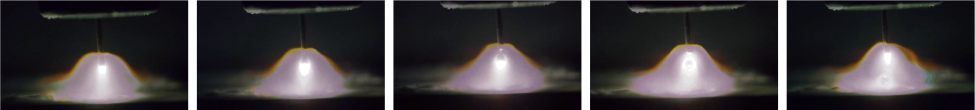

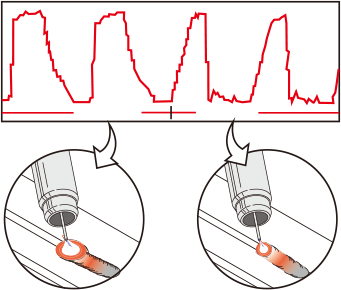

double Pulse MIG

Using Waveform Control Technology, the welding machine alternates between high and low energy pulses. This combination of high and low pulses produces the "rippled" bead appearance. The high energy pulses provide a hotter arc (longer arc duration), which improves cleaning action at the base material. The low energy pulses allow the weld puddle to cool, which controls the heat input for good penetration.

Advantage:

- Minimal distortion, even when gap conditions and wire placement vary.

- Outstanding control of arc characteristics, making it easier to produce excellent welds.

- Rippled bead appearance requires no weaving to produce a uniform bead.

- Controls the arc length and heat input together for excellent penetration profile.

- Controls the arc heat, making it ideal for welding thinner materials.

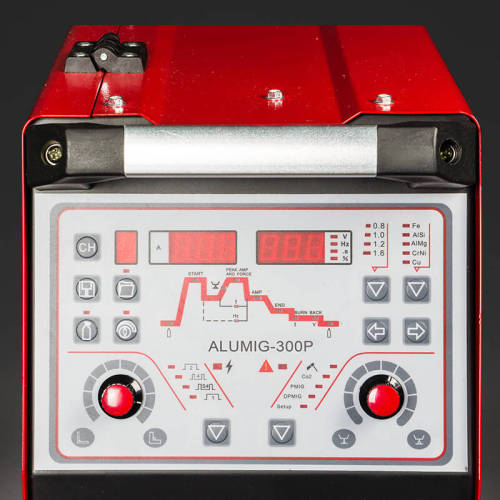

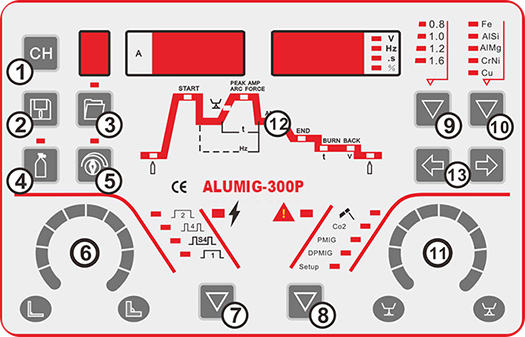

General View of Control Panel

1.SELECT the Memory channel

2.OPEN the parameter of selected memory channel

3.STORE the setting to Memory channel

4. Push to Check Gas

5.STORE Push to use Synergic Setting

6.Welding parameter setting,rotary dial

Adjudtment of the welding current or feeding speed.7.Torch Holding Mode Push to select the torch handing type:

1)2T 2)4T 3)S4:for aluminiu welding form cold to hot situation.

8.Welding Process Push to select:

Welding prcess:MMA,MIG/MAG/CO2,Pulse MIG,

Double Pulse MIG.

9.Dia. of Welding Wire

10.Wire Type

11.button,throttling effect(arc dynamics)

12.Function Sequence

13.Welding Settings

-

-

Item No ALUMIG-300P Rated Input Voltage 3PH ~ 400V ±15% Max. Load Power Capacity 12.04KVA Rated Duty Cycle(40℃) 60% MIG250A/26.5V MMA:250A/28V 100% MIG: 250A/26.5V MMA: 200A/30V Welding Current/Voltage Range MIG: 10A/14.5V~300A/29V MMA:10A/20.4V~250A/30V Open Circuit Voltage 55V Power Factor 0.85 Efficiency 85% Pre-Gas Time 0-15S Flow-Gas Time 0-15S Wire-feed Mechanism 4 Rollers Wire-feed Speed Range 0~25 m/min Wire Spool Capacity 300mm (15kg) Filler Wires Ø (mm) Fe, Ss: 0.6~1.2 mm FLUX CORED: 0.9~1.2 mm Al: 0.8~1.2 mm Dimension 790X250X650mm Weight 32KG -

-

Q:Are you a factory or a trading company?

A: We are factory with more than 10 years manufacturing experience and we provide perfect OEM and after-sale service.

Q:How can I pay my order?

A: We accept T/T, Western Union, Alibaba Trade Assurance payments. For those orders less than 1000USD, we accept PayPal to pay.

Q:How about your warranty?

A: We offer 3-year product life guarantee ,and a generous 1 year warranty on al purchases that begins with the bill of lading.

Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.

Q:How can I get the quotation?

A: We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price,please send the message on trade management or call us directly